This session is about Permit to Work Conducted by Green World Group with Mr. Fasih A Ahmed, HSE Trainer from Green World Group, KSA. This part gives detailed explanation on Permit to Work

Video Transcription

Work permit is a safe method of work practiced in a lot of organizations where either the activities restricted or the areas restricted.

It maintains the safe system of work. By issuing, receiving, transferring and clearing of all work permits for Pacific hazardous activities or hazardous areas, restricted areas again.

So there are two major reasons either the areas restricted or the activities restricted.

Areas restricted, that means there’s something very hazardous there or there could be multiple hazards.

“For example: a live electrical wire going, or maybe there’s some sort of energy that can either ignite or electrocute”

Activities restricted, what I mean is the activity in the sense that either you’re going to be grinding, there’ll be sparks admitted or there’ll be hot cutting and so on.

Now the restricted locations that have been designated by the division manager or the area supervisor or from higher management that is deemed to be restricted either to the activity. So we’re talking about energized substations, nearby energized transmission lines and a road crossing, power plants and so on.

Now, what is a word – Work Permit?

“It is actually a written agreement, or you can say it in the contract that authorizes certain people to carry out specific work after certain time or certain place that sets out mainly precautions needed to complete the job safely”

So it’s a good check-in balance between issuer and receiver. So the work permit is designed to protect personnel, working in hazardous areas or in a very special environment where certain precautions that I required to take a place ahead of executing the job right.

“So the work permit is actually a procedure that can reduce/eliminate the hazard”

But most of the times we can. So we try to reduce it and move on to the next step, which is hierarchy of control. So try to minimize or eliminate the incident that has the potential to cause incidents or injuries at a work site.

Now the work permit is not a JSA, which is Job Safety Analysis. It could be the restricted area as well as the first tip restricted activity within the restricted area, which is much more hazardous and means much more precautions.

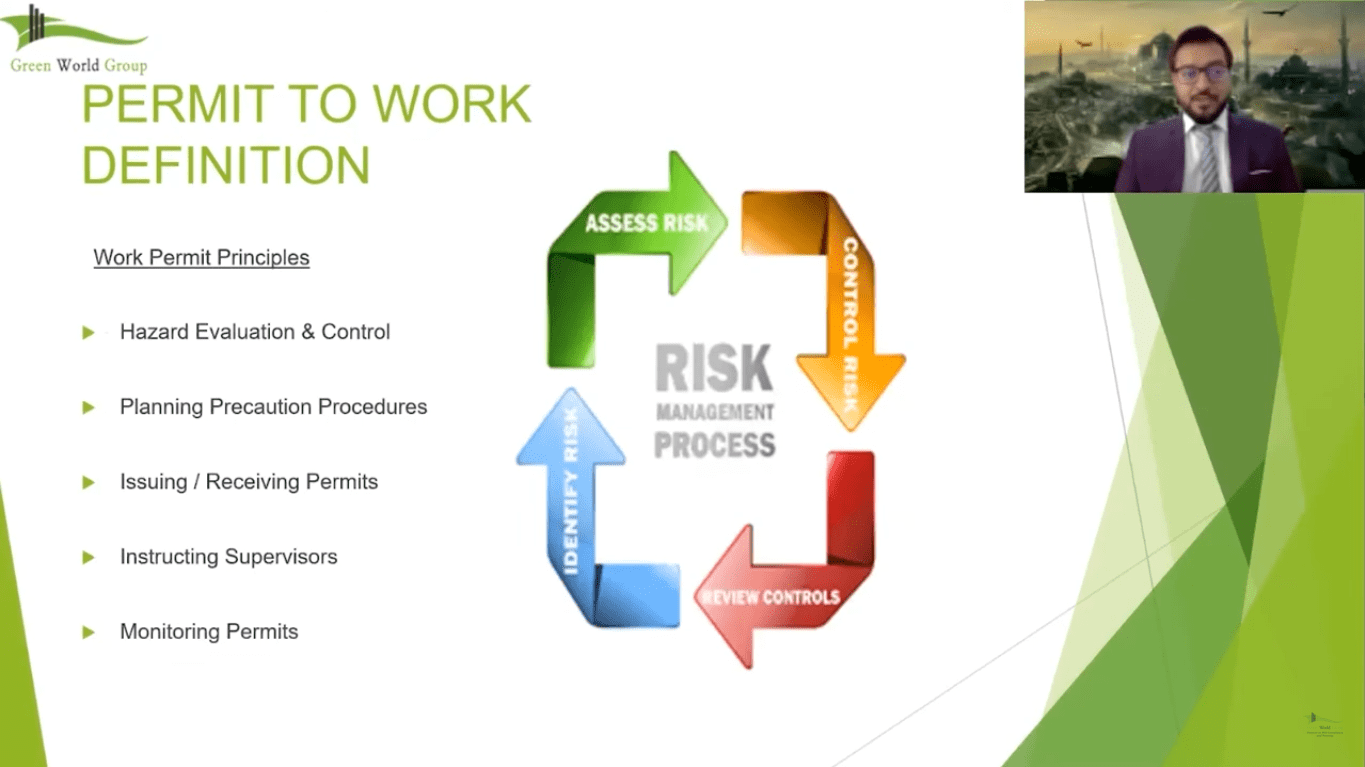

“So the pre basic principles that a work permit falls apart is that you identify the hazards and then you said controls tool”

Of course you can only set controls to something that you’ve identified, then planning, precautions, to those perspectives and then issuing and receiving those permits and then instructing the supervisors on the possibilities of incidents occurring from that.

But not only that, how that work should be done and how that process is a poor responsibility of the supervisor during that process of work and then monitoring those parts, because there could be multiple permits in the area.

This work permit system also allows the issuer itself, the owner that our area, to monitor how many permits are there.

Most of the times you won’t allowed to permit in the same area why because of it being very dangerous. So then it could conflict those activities that are in that area.

So who is the issuer?

The issuer is practically the owner of the place or someone appointed by the owner of who has the best understanding of that area.

So he knows already what is restricted?

What is the hazard within that area?

What the process is?

what’s going on?

what’s underneath the ground?

What’s above the ground?

what’s in the area?

Appointed issuer should have been well understood about that

Now receivers, who are they?

Receivers are the people who know the job and they are usually contracted and they could be subcontracted or they could be people within the organization, specialized in that activity.

So they know the job in and out. The competent people know the job. Now this could be the supervisor, it could be the permanent receiver in charge, could be the foreman itself who’s trying to always be who will be doing the job.

So his job is to receive the permit state of what he requires for the job, what are the hazards that will arise from his activities, which would need certain set of precautions.

Now let’s talk about the different types of permits

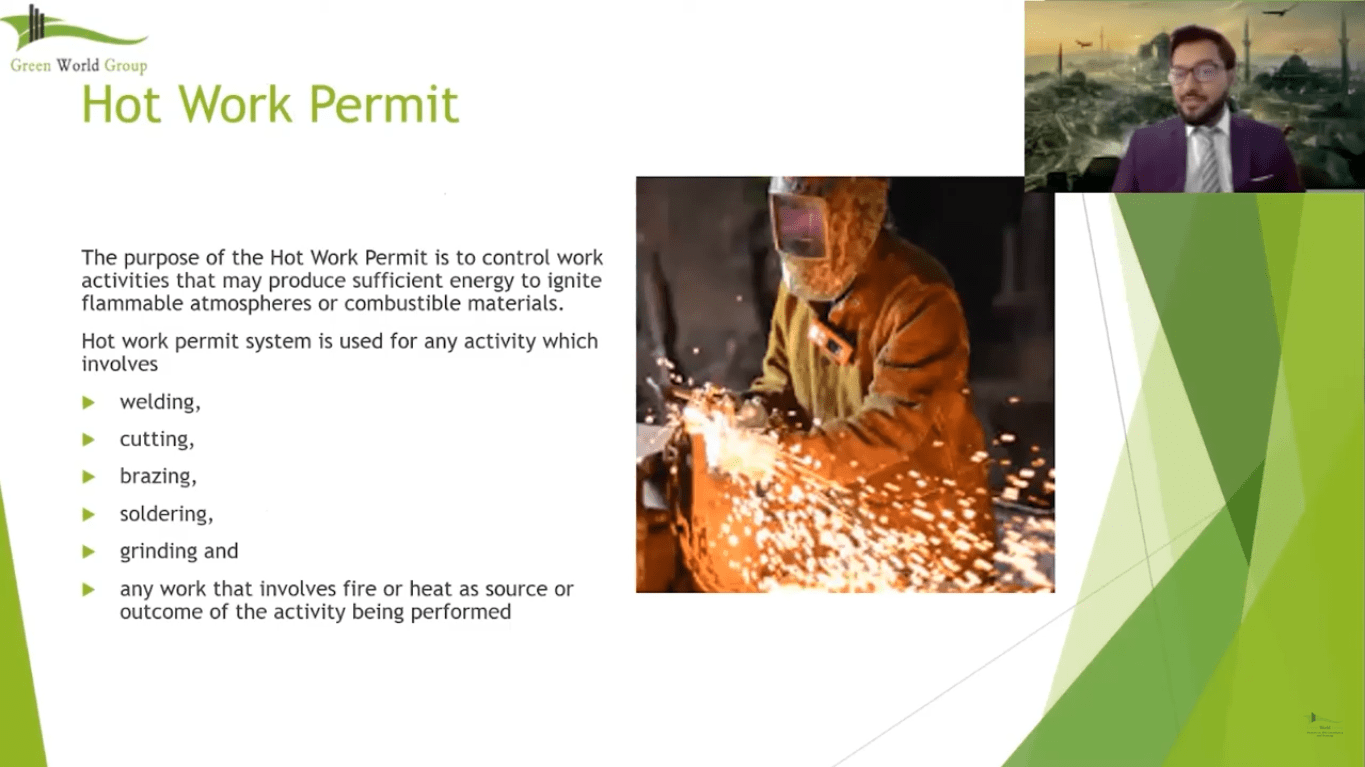

So the Hot work permit could be,

Activities where welding, cutting, blazing, soldering, grinding, any activities that has sufficient energy that can ignite into flour and black atmospheres or combustible materials. So either the area has potential danger or the activity does and that’s what the hard work permit is.

Cold work permit is very simple

It’s anything that could be hazardous in terms of inhalation and so on. So there’s no chance of ignition, but there may be lack of something that is atmosphere hazardous to us.

Maybe there might be a deficiency in the oxygen, there might be gases in the atmosphere, or maybe if you’re doing a painting job within a room – that could be a cold work permit.

Now let’s talk about electrical permits

Usually we would use the process of lockout – tag out for electrical purposes, but the electrical permit is for electrical jobs.

Whenever we do a repair work or maintenance work on machines that are generated by electricity, we would always try to process that or try to conduct work on it, by using the lockout tag out process.

Lockout tag out process is a very brilliant process because when we’re doing maintenance work and nobody’s standing up the on switch, people accidentally pressed that, there could be a lot of danger that can be transmitted and cause injury and may be fatality in more spaces.

So we came up with a process of lockout tag out again, we’re going to be explaining all of this in much more detail, if you decide to take the course with the Green world group.

Then we have the excavation permit

Now the excavation permit is for excavating obviously below ground and we have possible dangers where people can be in golf by the swell that they’ve dug into.

“Any excavation that is more than four feet would be considered a confined space”

There are engineering controls to excavations, where we can use showing, we can use a sloping, we can use the benching, and again, I can explain all of these terms, when you decided to take this course with the Green World Group.

So moving forward very quickly, let’s go to Confined Space to Entry Permit

There’s the confined space where we’ve identified something to be a confined space. And then there’s the confined space entry permit, which allows us to enter into that confined space with proper training and proper induction.

But to define a confined space, we need to ensure that a confined space is something that could not be occupied by people, has a very limited entry and exit, and was not designed for human occupants.

So, there are certain measures that we must take and perform gas testing, we must perform the proper identification of the hazards and the evaluations, and then apply proper controls in order to enter the confined space.

So moving forward, then we have the Lifting Permit

This will allow us to lift adequately and safely, to do jobs in terms of moving, maybe loads from one place to another in the safest way.

Now this would require us to inspect the quality of the crane, the quality of the boom, quality of the slings, to ensure that we are lifting it properly, the angle of the boom, all these factors are very crucial to ensuring the job to be done very safely.

So this is the safe method of work that we must initiate, when we are working in restricted areas or with restricted activity.

Working at height Permit

The same concept of place, but not only that, there are also precautions that we must take that if something happens, how would we perform the rescue. So there must be an emergency rescue plan in place as well and the work permit allows us to do that.

So we are taking precautions and we are ensuring that the proper PPE is there being used, the proper tools are being used, the proper means of getting up there is being used as well.

So here we are with a cold work permit again

This is a permit that works with the activities, to produce, but nothing that is flammable but could be hazardous in terms of inhalation, most over making a scaffold or erecting a scaffold, brush painting or repair work. Again you can issue this permit in a restricted area, which has these hazards or the activity itself.

So, how does this work permit process work?

Now, suspension or cancellation of work permit – This again happens when something has gone of a schedule or something has gone wrong.

So either there has been injury or an incident that has occurred, for which the permit would be either canceled or suspended. And then clearance of the work permit would be when the job is done.

Both issuer and receiver come back to the site and seeing everything that has been adequately completed as well as housekeeping has been done and everything’s been back to normal, then yes, the final signature for closing that permit has been done.

Issuing and acceptance of the permit

Meaning, identifying which permit would be best suited for that area or that activity, understanding that, not only performing a joint site inspection with the issuer, as well as the receiver.

They both go to the site why we need both of these people for the reason that one knows the area very well and the other one knows the activity so they can join together to understand, to identify these hazards related to their line of work.

Filling and Required document

The second step is they fill out the required documents most accurately, and honestly as possible.

Displaying the work permit

Meaning, identifying which permit would be best suited for that area or that activity, understanding that, not only performing a joint site inspection with the issuer, as well as the receiver.

They both go to the site why we need both of these people for the reason that one knows the area very well and the other one knows the activity so they can join together to understand, to identify these hazards related to their line of work.

Then we have the Validation of work permit

Usually one-day work is usually eight hours. Now, depending on the severity of the job, maybe it could be a confined space where we can limit the duration of how long we want our workers to be exposed to the hazard within it.

So we can limit it down to depending on that project, but we can also have it for four hours. Again, usual duration of a work permit is for eight hours, which is one shift.

Then the cancellation or a suspension of a work permit

If an unsafe condition occurred develops, when either the issuer or the receivers are available at the work site, then the work permit could be suspended, meaning stop work has occurred either for that emergency reason or either for the whole areas.

Plant-wide alarm maybe has gone off, emergency has occurred somewhere else and everybody has been asked to evacuate, that is also a suspension. So until the all-clear is not given, they cannot resume the work. So the work permit would be suspended for that time period.

Final clearance

I’ve already explained before, but the work permit shall be authorized by the issuer & receiver because they’re the ones from first initiated the work at permit. So it only is fitting that they should be the ones to complete.

So again, with both parties agreeing to, that the job has been completed adequately, and there’s nothing left behind. So once the area has been returned to its pre-work condition, then the work will be signed off by both parties and the permit will be closed.